A team of scientists at POSTECH (Pohang University of Science and Technology) has developed a remarkable new material that challenges the limitations of traditional metals. Under the leadership of Professor Hyoung Seop Kim, the team has engineered a high-entropy alloy (HEA) that maintains its strength and flexibility across a broad temperature spectrum—from an icy –196 °C up to a scorching 600 °C.

This innovative breakthrough, recently published in Materials Research Letters, could transform industries such as aerospace, automotive, and energy, where materials often need to withstand extreme and sudden temperature changes.

A New Frontier in Materials: The “Hyperadaptor”

Conventional metals are highly sensitive to temperature fluctuations, often becoming brittle in the cold or losing strength in the heat. This poses challenges in environments like jet engines, space vehicles, and energy systems. The POSTECH team tackled this issue by introducing a novel concept called the “Hyperadaptor.” This concept centers around the creation of a temperature-insensitive alloy—one that delivers reliable mechanical performance regardless of external conditions.

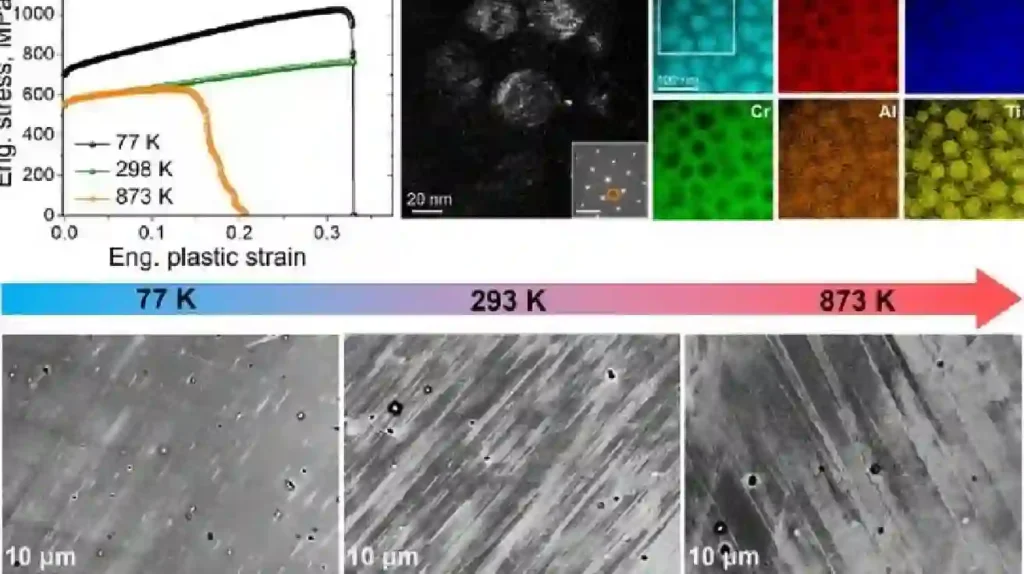

The result is a nickel-based high-entropy alloy that demonstrates exceptional resilience and adaptability. What sets this material apart is its internal nanostructure: it contains evenly dispersed nanoscale L1₂ precipitates that act like microscopic reinforcements. These particles help prevent deformation and ensure that the alloy deforms in a stable, predictable manner under stress—whether it’s subjected to deep cryogenic cold or high industrial heat.

Why This Matters

Materials that can retain their mechanical properties across wide temperature ranges are in high demand, especially for systems exposed to frequent and extreme thermal cycling. The aerospace sector could use this alloy in rockets and turbine engines. Automakers may find it ideal for components near exhaust systems. Power plants and energy companies might rely on it in pipelines or turbines where durability under thermal stress is critical.

By eliminating the temperature limitations of conventional metals, POSTECH’s Hyperadaptor alloy not only boosts safety but also opens new avenues for innovation in high-performance environments.

A Leap Toward the Future of Engineering Materials

“This high-entropy alloy represents a new era of material science,” said Professor Kim. “Its consistent performance under extreme conditions demonstrates what the future of engineering materials can look like. The Hyperadaptor sets the foundation for next-generation solutions that are both efficient and reliable.”

The project received support from Korea’s Ministry of Science and ICT under the Nano and Materials Technology Development Program and also gained backing from Hyundai Motor Group—highlighting its real-world relevance and commercial potential.

As industries continue to push boundaries in performance and safety, materials like POSTECH’s Hyperadaptor alloy will be at the core of these technological advances.